Modern people have increasingly high requirements for living standards, and various aspects of kitchen utensils are becoming more customized. In order to further improve the qualification rate of castings, manufacturers use three-dimensional measurement methods to inspect castings.

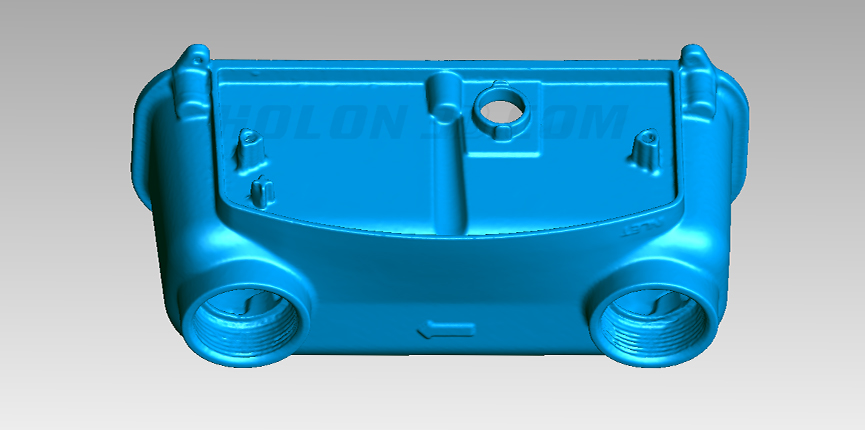

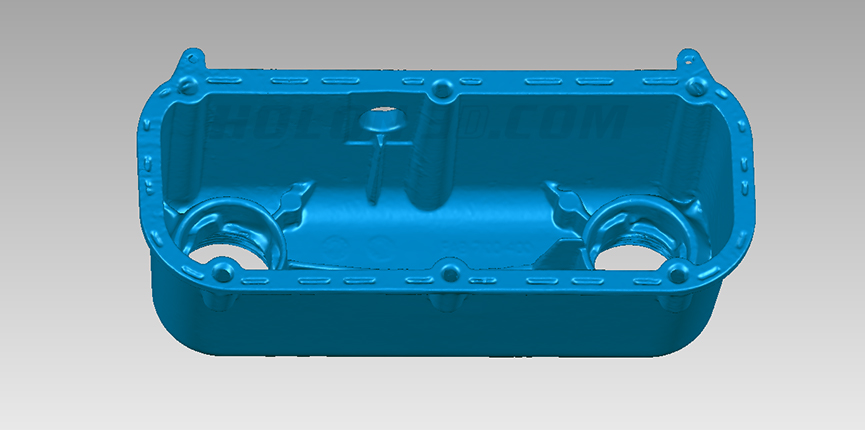

Physical picture of stove casting shell

Practical problems

The manufacturer adopts a sampling method for measurement, requiring the testing process to be simple, fast, and easy to use.

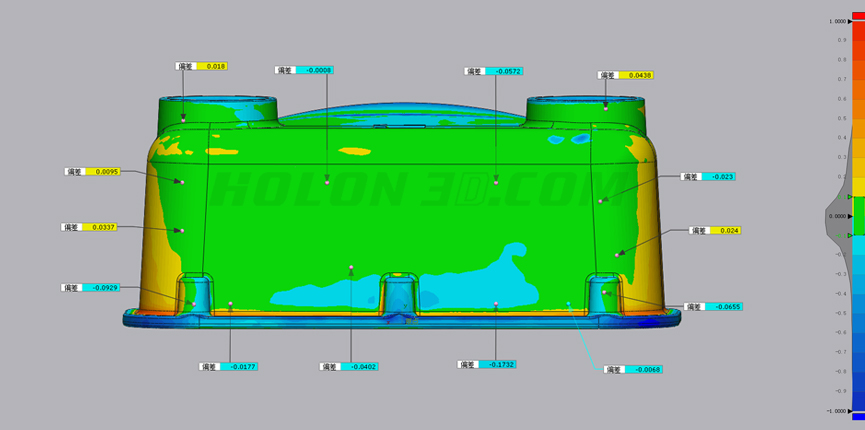

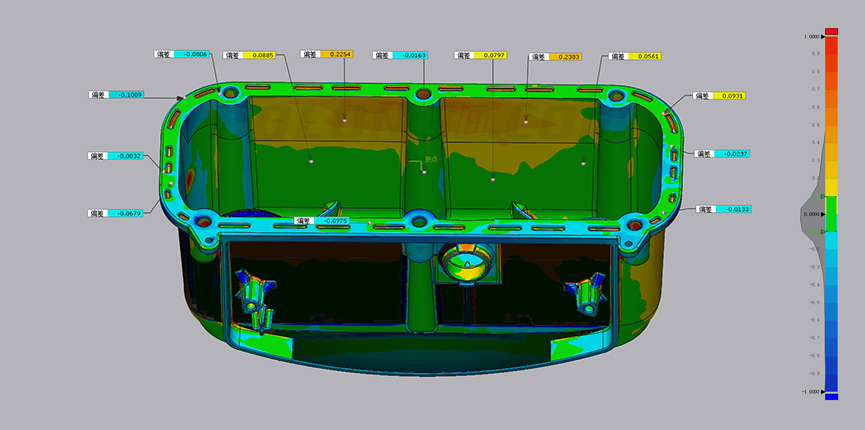

The accuracy of the stove shell is related to the installation of finished kitchen utensils in the later stage, and there is a high requirement for casting accuracy.

Physical picture of stove casting shell

Holon solutionsUsing handheld non-contact scanning to quickly scan the shell of kitchen utensils, the built-in precision mode easily obtains narrow dead angle data of castings, restores the original 3D data of castings one by one, and imports detection software with one click to quickly obtain detection reports. The industrial intelligent design is simple to use, and you can master the operation of the scanner in about 2-3 working days.

The wave of 3D digitization has affected all aspects of our lives. With its powerful measurement capability, the handheld 3D scanner can easily solve various detection problems in industrial manufacturing and help the manufacturing industry develop rapidly and efficiently.

STL data diagram of stove casting shell

STL data diagram of stove casting shell

Comparative inspection diagram of stove casting shell

Comparative inspection diagram of stove casting shell