The 19th Shanghai International Casting Exhibition has come to a successful conclusion. In the future, we will work hand in hand and embark on a new journey!

The 19th Shanghai International Casting Exhibition, which lasted for 3 days, was successfully held at the Shanghai New International Expo Center from November 29 to December 1, 2023. Hualang 3D showcases advanced handheld 3D scanners, automated 3D detection systems, and professional 3D measurement solutions.

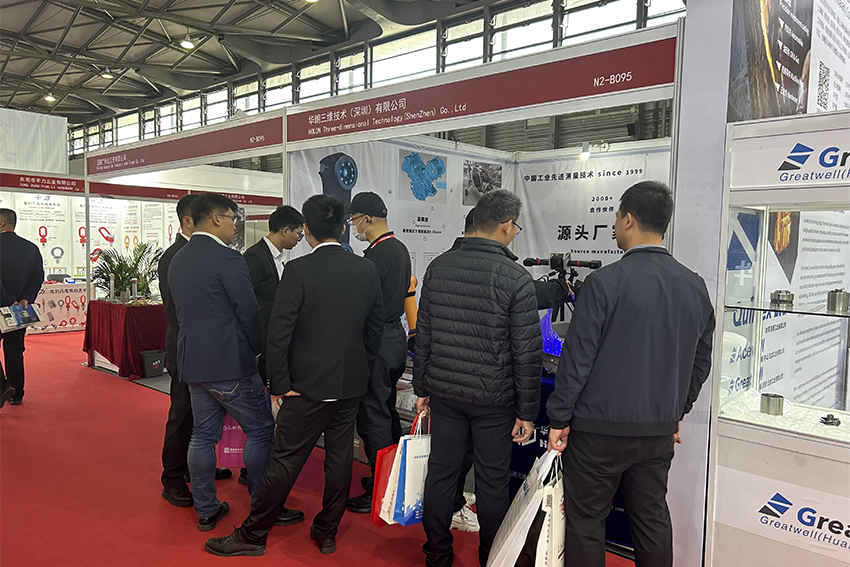

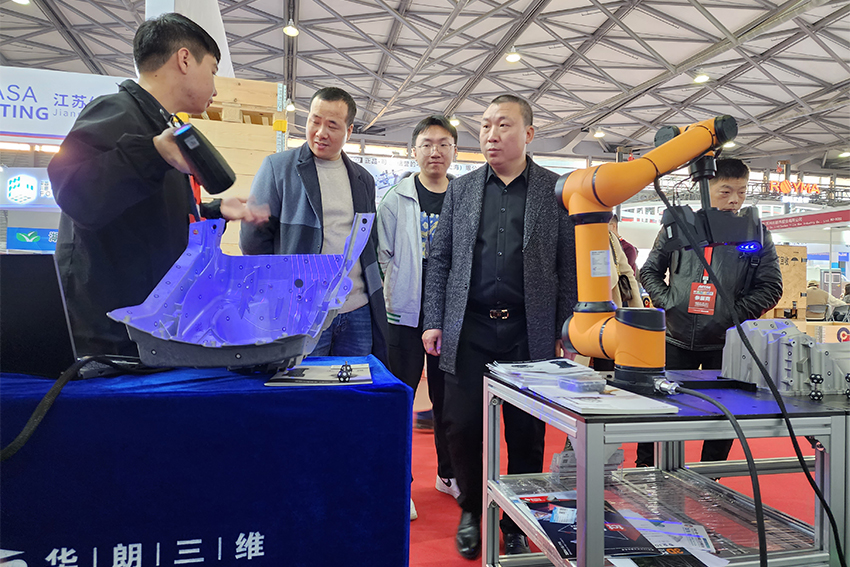

The Hualang 3D team conducted on-site demonstrations for clients and exchanged ideas on the application and development of 3D digital technology in the field of quality manufacturing. The exhibition site was exciting and full of highlights!

The Shanghai International Casting Exhibition was founded in 2005 and has been successfully held for 18 sessions. The exhibition covers the fields of castings, casting molds, casting materials, casting equipment, and casting accessories. At that time, 700 casting and related enterprises gathered, with an exhibition area of 40000 square meters and over 30000 professional visitors. The exhibition will invite Chinese and global casting manufacturers to showcase new products, technologies, and equipment in accordance with the requirements of "internationalization, specialization, and high-level". This will help industry executives fully understand the latest trends in the global casting industry chain, and create a one-stop procurement platform for products, materials, and equipment for visitors!

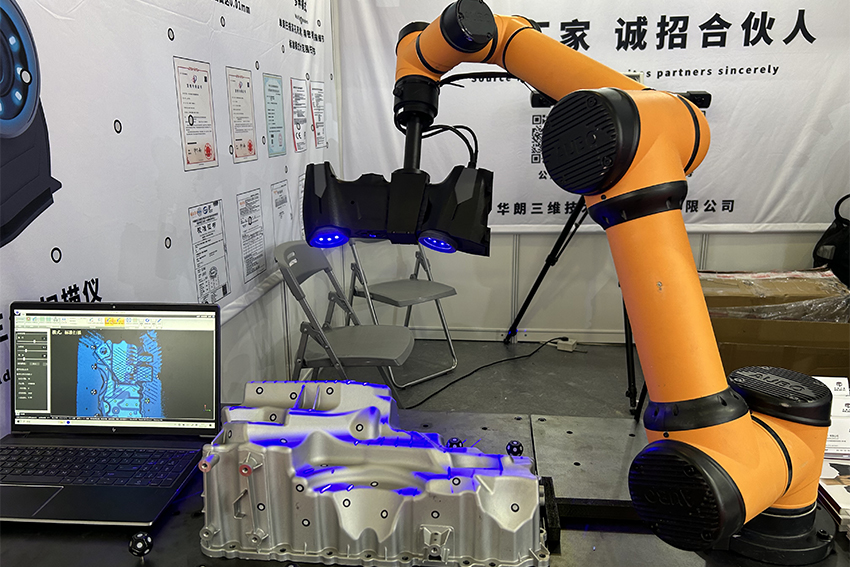

Hualang 3D showcased a full range of handheld 3D scanners and 3D measurement solutions, including the handheld 3D scanner HOLON B71, near-infrared 3D scanners, automated 3D scanning, etc. The booth attracted numerous visitors to inquire and exchanged views with on-site staff on the widespread application of Hualang 3D products and solutions in the field of quality control.

Adopting the latest handheld design, lightweight, and extremely easy to carry: using 22 laser beams+1 beam scanning deep holes+7 beams scanning details, a total of 30 laser beams are used, with fast scanning speed, high accuracy, and strong stability. Equipped with dual industrial cameras, automatic splicing technology of landmark points, and independently developed scanning software, it has ultra-high scanning accuracy and work efficiency. It is widely used in reverse engineering and 3D detection fields, with flexible and convenient operation, Suitable for various complex application scenarios.

As an automated intelligent detection system for rapid batch processing, automated 3D scanning is designed specifically for near line detection and intelligent measurement. It can be seamlessly integrated into automated measurement and quality control processes, ensuring ideal measurement accuracy and speed. It can accurately and quickly detect quality problems, making detection more automated, data-driven, and intelligent, helping enterprises achieve cost reduction and efficiency improvement, and helping manufacturing enterprises make quick decisions, Control product quality early and effectively solve productivity issues.

Handheld design, easy to carry, and easy to use; Industrial grade large-scale 3D scanning system with high work efficiency, can flexibly develop scanning plans according to user needs. At the exhibition site, staff will demonstrate the scanning process of near-infrared 3D scanners to the audience and provide in-depth explanations.

At the exhibition site, all participating parties had full exchanges and interactions around the products, technologies, and services of the casting industry, and the atmosphere inside the exhibition hall was lively.

This exhibition has attracted professionals and industry experts from all over the country to attend, and nearly 10000 visitors have made reservations to attend.

At this exhibition, Hualang 3D showcased advanced 3D digital technology, providing intelligent manufacturing enterprises with more precise, flexible, efficient, and highly portable 3D data acquisition solutions that can be applied to various links in the intelligent manufacturing industry chain, such as 3D inspection, reverse modeling, reverse design, etc., to reduce production costs, optimize processing processes, and shorten delivery cycles for manufacturing enterprises.

As a professional provider of 3D digital products and solutions, we strive to bring the latest 3D scanning technology achievements to the world, and empower manufacturing enterprises with high-quality development through the popularization of high-precision 3D vision technology.